Zero Defects Manufacturing

All manufactured items should be correctly made, with all processes and parts within specified tolerances, however manufacturing errors can occur

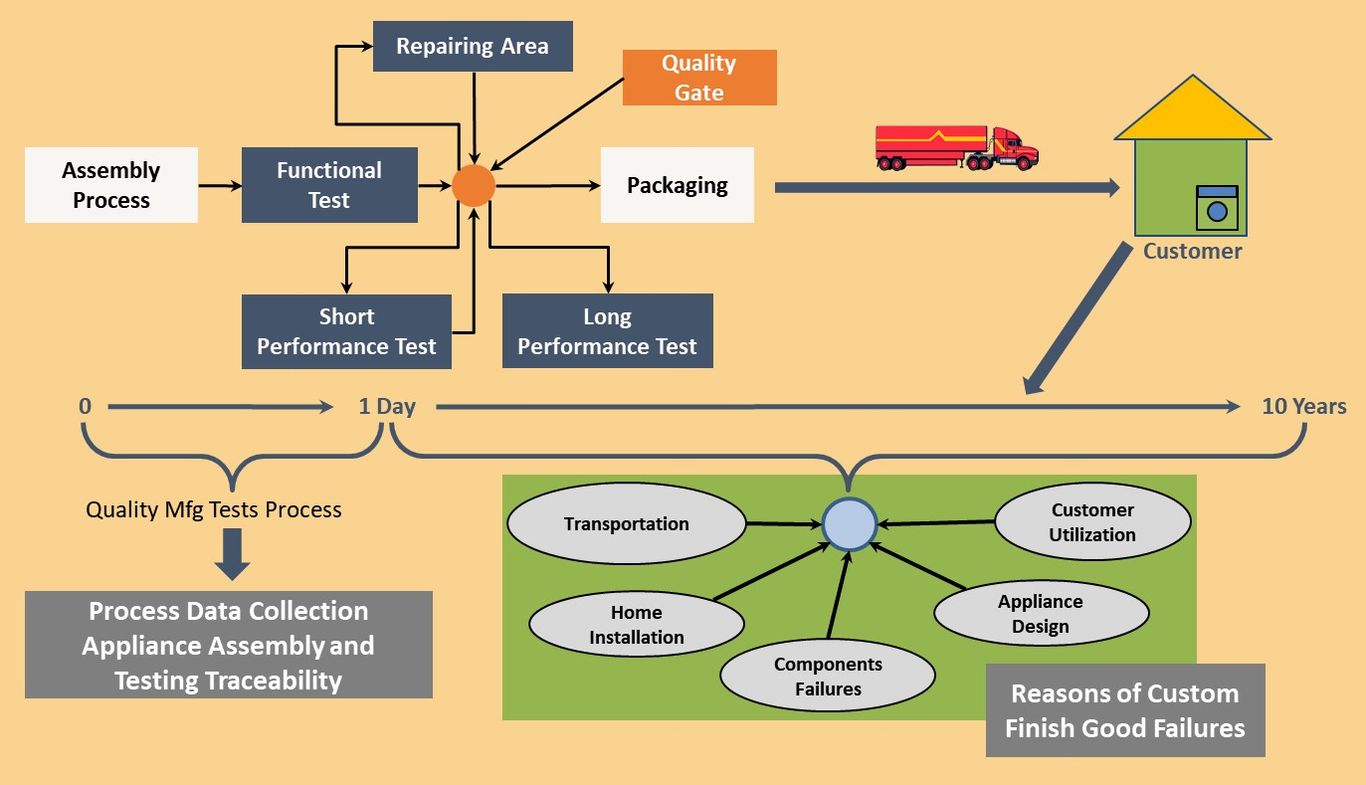

We must determine the inspection and test methods that will most effectively and economically identify these. Testing adds to manufacturing costs, and therefore should be reduced to the minimum that is necessary to minimize the downstream costs of defects and failures that would otherwise arise

- There are two kinds of defective items that can be produced

- Those that do not work initially, or that can be identified as defective by inspection and measurements

- Those that pass the initial inspections and tests but contain defects that could be cause of failures later

- Testing is an essential element of manufacturing, because:

- Manufacturing Processes Generate Variation and Defects

- The Costs of Defects later in the product life cycle might exceed the cost of the tests and rectification during manufacturing that could prevent them

- Need to ensure accurate and correct performance

- The manufacturing tests should not include tests for design of the product, because the adequacy of the product design should have been confirmed by the product development phase tests

- The Manufacturing Tests should not be copies of the tests applied in development, but should be optimized in relation to the engineering and economics of manufacturing for mass production repeatability

- The information gained in development testing should be applied to optimize the manufacturing test

- Any tests performed must detect defects of failures generated by the manufacturing processes, without damaging or reducing the useful life of good items. This is a fundamentally different requirement compared with that for development testing

© Copyright , all rights reserved

Abbiamo bisogno del vostro consenso per caricare le traduzioni

Per tradurre i contenuti del sito web utilizziamo un servizio di terze parti che potrebbe raccogliere dati sulla vostra attività. Si prega di rivedere i dettagli nell'informativa sulla privacy e accettare il servizio per vedere le traduzioni.